Product Overview

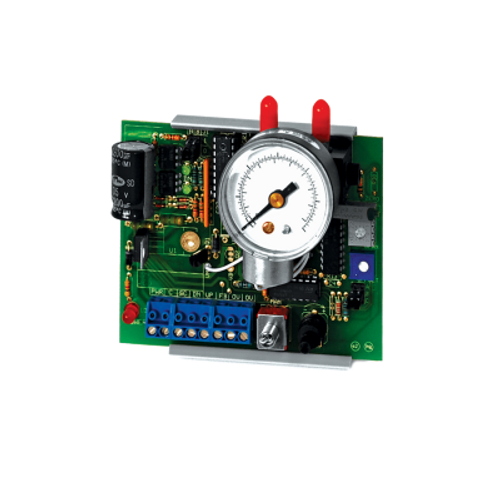

The PTS4.1 converts two digital (increase/decrease) signals from relay contact closures, transistors, or triac inputs into proportional pneumatic signals of 0-10, 5-15 or 0-15 psig or 0-69, 34-103, or 0-103 kPa (jumper selectable). The pneumatic output increases when the UP input is on, or decreases when the DOWN input is on. The pneumatic output changes full scale (from minimum to maximum) in 90 seconds, with 255 steps of resolution. The PTS4.1's closed loop electronic design will maintain the last commanded pneumatic pressure. An on-board microprocessor measures the signal input, and a solid-state pressure transducer measures branch line pressure. The PTS4.1 uses these two values to automatically increase or decrease branch line air pressure. In the event of a power failure, both PTS4.1 valves close, shutting off main air and branch line bleed. If a power brown-out occurs, the PTS4.1 automatically reboots (resets) its on-board processor. During a power brown-out, power to the processor on the PTS4.1 is shut down (pressure output remains same). When proper power level is restored, processor automatically powers up, and branch pressure output defaults to 0 psig. The PTS4.1 is covered by ACI's Two (2) Year Limited Warranty.

- Compressor staging applications

- Closed loop control

- Compressor staging applications

- Closed loop control