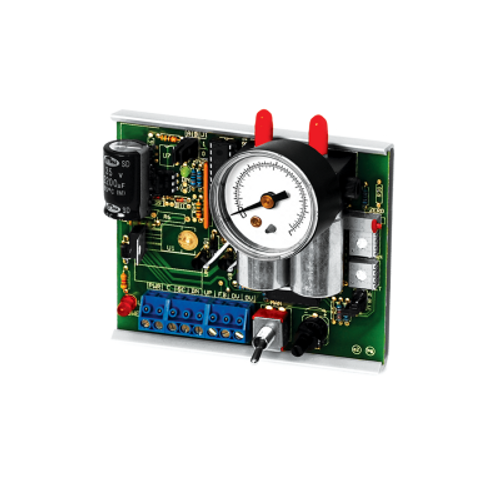

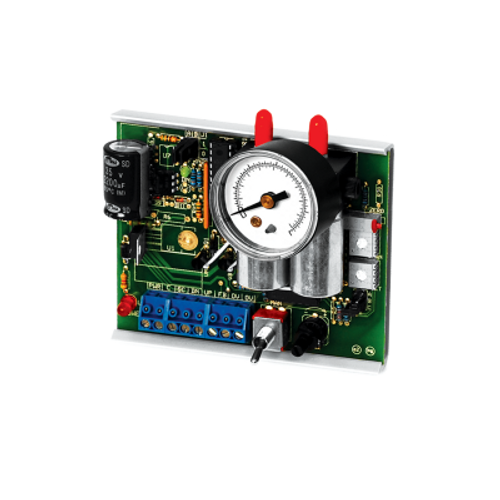

Product Overview

The EPW* converts a pulse, phase cut, or digital PWM signal into a proportional pneumatic signal ranging from 0 to 20 psig. The pneumatic output is proportional to the signal input, either direct or reverse acting. The EPW* has a manual override potentiometer to vary the pneumatic output and two LEDs, one to indicate power and one for signal status. The EPW* offers four jumper selectable input timing ranges. Output pressure ranges are jumper shunt selectable for 0 to 10, 0 to 15 and 0 to 20 psig, and adjustable in all ranges. A 0-5 VDC feedback signal indicating the resultant branch line pressure, is also provided. This signal varies linearly with the branch pressure range selected. EPW* is designed with electrical terminals on one end and pneumatic connections on the other, allowing for maximum convenience in wiring and tubing installation when panel mounted. Three basic configurations are available: The EPW is a constant bleed interface with branch exhaust response time determined by the bleed orifice size and pressure differentials. If power fails to the EPW, it will continue to bleed through the bleed orifice until branch pressure is zero psig. The EPW2 incorporates two valves (one controls exhaust) and does not bleed air at set point. Its branch exhaust flow and response time are not limited by an internal restrictor and are similar to its load rate. If power fails to the EPW2, branch line pressure remains constant if the branch line does not leak air. FAIL SAFE: The EPW2FS is a two valve fail safe model. Its 3-way branch exhaust valve allowsm exhaust of branch line air on a power failure.,All factory calibrated products are NIST traceable. Certificates of Compliance must be ordered with product. EU Commission Directive 2002/95/EC (RoHS) Compliant.

- Three way mixing valve control

- Pilot positioner control

- Compressor staging

- Three way mixing valve control

- Pilot positioner control

- Compressor staging